Introducing the ARGOS

IN-ROUTE CABLING

Clean lines and an even cleaner drag profile. The front end is kept neat with an Enve Composites aero stem and bars as standard with optional upgrades to an In-route One Piece cockpit.

COMFORT MEETS AERODYNAMICS

Comfort coupled with performance. A junction engineered around the now infamous Enve Composites D-Shaped design. Optimized aerodynamics and compliance. With three post lengths and two setback offsets, there is a post for all frame sizes and riding positions.

TITANIUM T47 BOTTOM BRACKET

We've seen a lot of bottom bracket standards come and go. For us, we wanted to keep it simple and eliminate any chance of oxidization at the same time. We encorporated a titanium T47 bottom bracket shell to keep the drivetrain aligned and hassle free.

FRAMESETS STARTING FROM $12,490AUD*

COMPLETE BUILDS STARTING FROM $17,490AUD*

PRODUCTION ROLLOUT SCHEDULED EARLY 2026

Standard Options

Modular carbon composite design

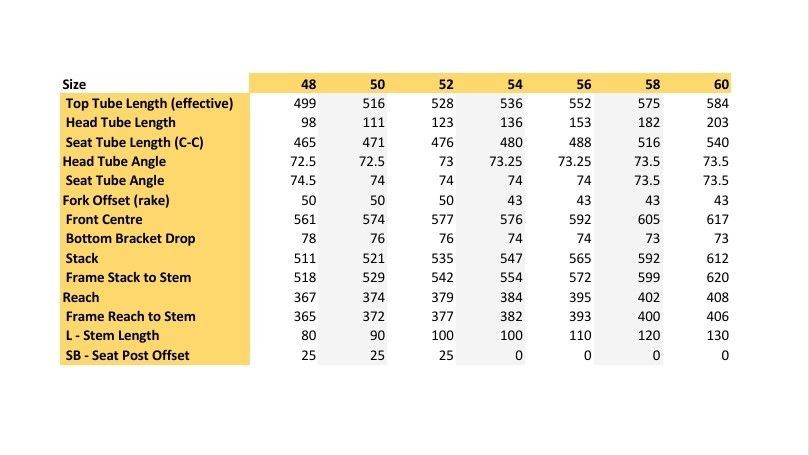

Choice of 7 standard sizes

standard level 1 colour scheme

Internal cable routing

Flat mount disc brake

Shimano Di2, Sram AXS, Campagnolo EPS compatible

Titanium T47 threaded bottom bracket shell

UDH compatible rear dropout

ENVE In-route disc through axle fork 100 x 12

ENVE In-route aero stem + bars

Enve aero seatpost

Maximum tyre size 35mm measured*

Additional Custom Options

Personalized in-house bike fit

Custom geometry*

Personalized options on level 2 paint scheme

ENVE In-route One Piece Handlebar upgrade

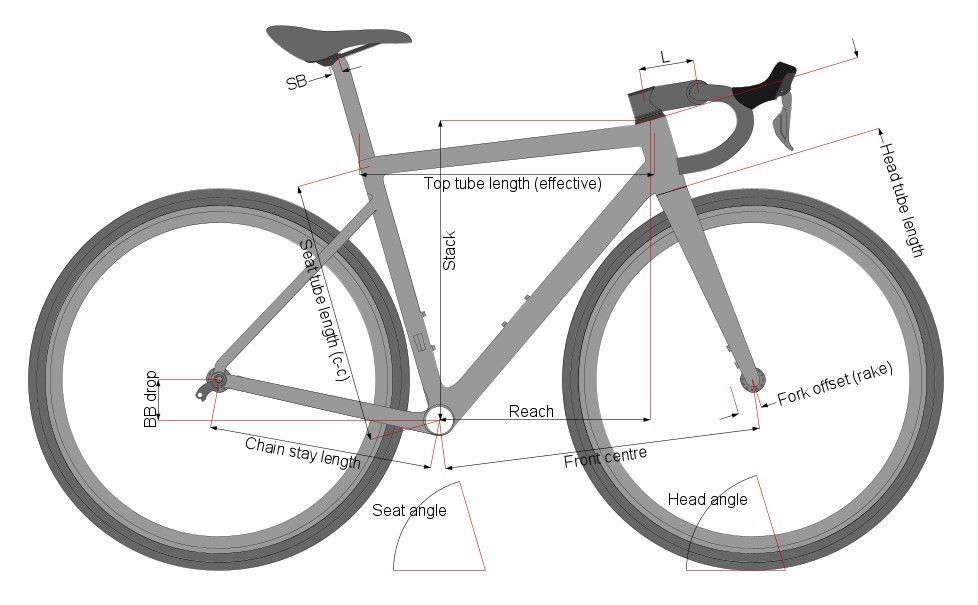

GEOMETRY